PERISTALTIC PUMPS

Peristaltic pumps (tube pumps) can be used for many purposes and are characterised by being safe and easy to use.

They can be used for a variety of tasks, for pumping nearly all liquids including highly viscous fluids, fluids containing large amounts of solid particles, corrosive liquids and for pumping sterile liquids.

Although your desired configuration is not in stock, can be delivered in about two weeks.

CHOOSE TYPE OF PERISTALTIC PUMP HERE

Catalogs

Please see the complete range of pumps in the following catalogs.

SHENCHEN CATALOG 2023 - PDF

LONGER CATALOG 2023-2024 - PDF

Please contact us if your require a price or have further questions for the pumps in the catalogs.

DESCRIPTION OF PERISTALTIC PUMPS

How does a peristaltic pump work?

A peristaltic pump configuration consists of three parts:

- Pump drive

- Pump head

- Tubing

Peristaltic pumps are suitable for pumping various fluids with great accuracy. One of the great advantages is that the fluid does not have any direct contact with the pump as it is only being transported inside the tubing. Thus it is easy to keep your pump clean.

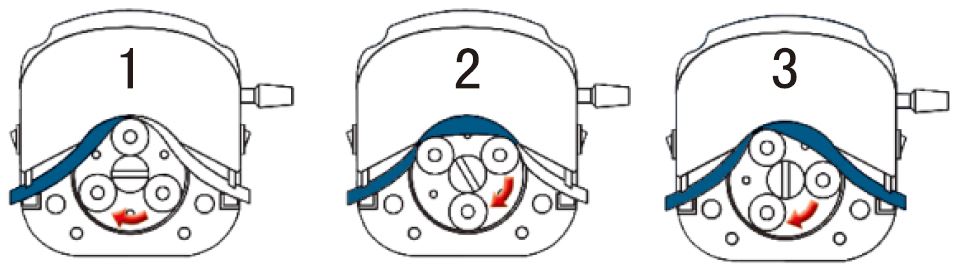

The illustration below shows a pump head with 3 rollers and a tubing. The rollers in the pump head compress the flexible pump tubing and as the rotor turns the rollers, the fluid is forced to move through the tubing.

Peristaltic pumps are distinguished by

- No fluid or pump contamination

- Tolerates running dry

- No valves that block or hang

- No seals which can leak

- Prevents backflow

- No rinsing and cleaning

- Rapid changeover to new tasks

- Peristaltic pumps are available with between 1-24 channels and are self-priming down to 8 metres in depth and the pumps can rotate both ways.

The peristaltic pumps are characterised by almost pulsation-free pumping with a 10-roller pump head. They are micro-processor controlled, which allow for precise dosing.

Typical industries and applications

| Industries | Applications |

| Beverages Biotechnology Chemical Environmental Food Ink Paint Pharmaceutical Plating Printing | Analytical Fermentation Filtration and separation Galvanic processing Research and development Water and waste water treatment |

If you have any questions or need more information, please contact us!