Guide for choosing tubing size

What to consider when selecting a peristaltic tubing?

- Deliver aggressive liquid or organic solvent: Use the chemical compatibility table from the link below to choose the right material.

- When working with suction lift or pressure: Select tubing with thicker wall thickness.

- Viscous liquids: Select tubing with thicker wall thickness and bigger inner diameter.

- High precision requirement: Select the tubing with the smallest inner diameter that can meet the flow rate requirement.

- If precision requirement is not very high: Select tubing with bigger inner diameter to decrease the speed of the drive which can decrease the wear of the tubing and prolong the service life of the tubing.

- Tubing bears pressure: Thinner wall thickness bears less pressure. Tubing with bigger inner diameter bears less pressure than tubing with smaller inner diameter with the same wall thickness. The pressure bearing ability in intermittent conditions is better than in continuous conditions.

Chemical resistance of tubings

ISMATEC and Masterflex Pump Tubing Selection Guide - PDF

IMPORTANT

You should always test the tubing with your chemicals for 48 hours before using it in your production. Temperature, pressure and concentrations can affect the shelf life.

Drifton and our pump suppliers are not responsible for any damage to the pump in the event of a tubing leak.

Factors which influence the flow rates

- Viscosity: The maximum viscosity a peristaltic pump can handle is about 2000 cps. The higher the viscosity, the lower the flow rate. It is recommended to use a tubing with a wall thickness of 2.4 mm or larger and a larger inner diameter than if you were pumping water.

- Suction Lift: A suction lift exists when the liquid is taken from an open to atmosphere tank where the liquid level is below the centerline of the pump suction. The higher the suction lift, the lower the flow rate. When the suction lift is more than 2 meters it will influence the flow rate noticeably.

- Delivery Lift: The higher the delivery lift, the lower the flow rate. The delivery lift influence the flow rate less than the suction lift.

- Tubing: New tubing has higher flow rate than older worn tubing.

- The flow rate is linear with the revolution per minute of the drive. If the rpm increases 1 time, the flow rate increases approximately 1 time.

How to calculate a peristaltic tubing size for liquids containing particles

The size of soft particles <25% * ID (tubing inner diameter)

The size of hard particles <5% * ID (tubing inner diameter)

Choose the tubing size according to your flow requirements

Under each peristaltic pump you will find a table with tubing sizes and flow rates which makes it easier for you to choose the apropriate tubing size.

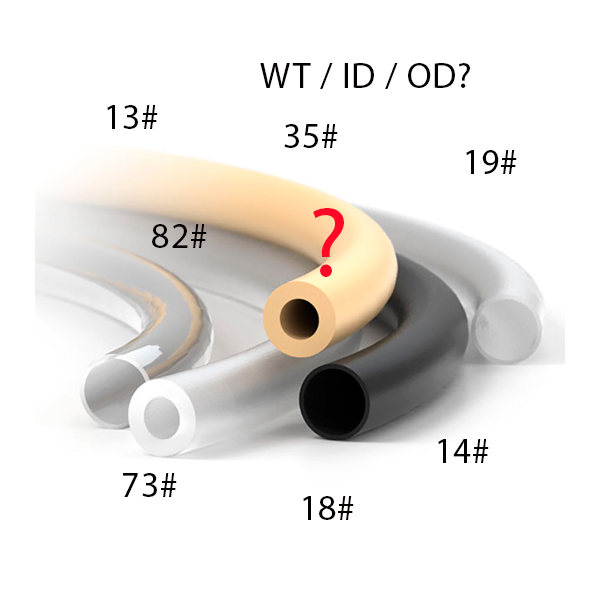

Tubing specifications

WT - wall thickness

ID - inner diameter

OD - outer diameter

Tubing sizes for micro flows

Tubing sizes for standard flows

Tubing sizes for industrial use with a high flow

See our selection of pump tubings.